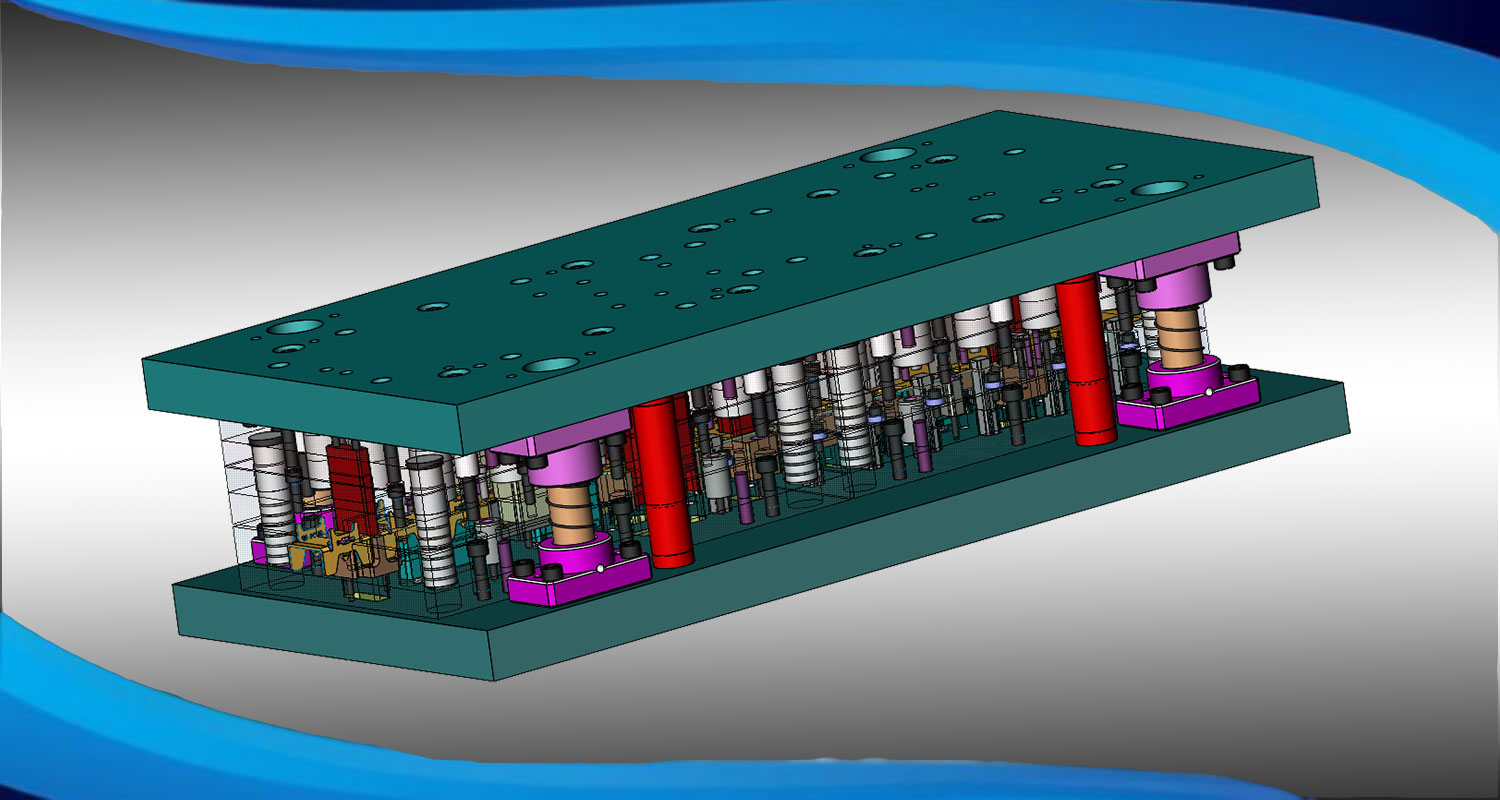

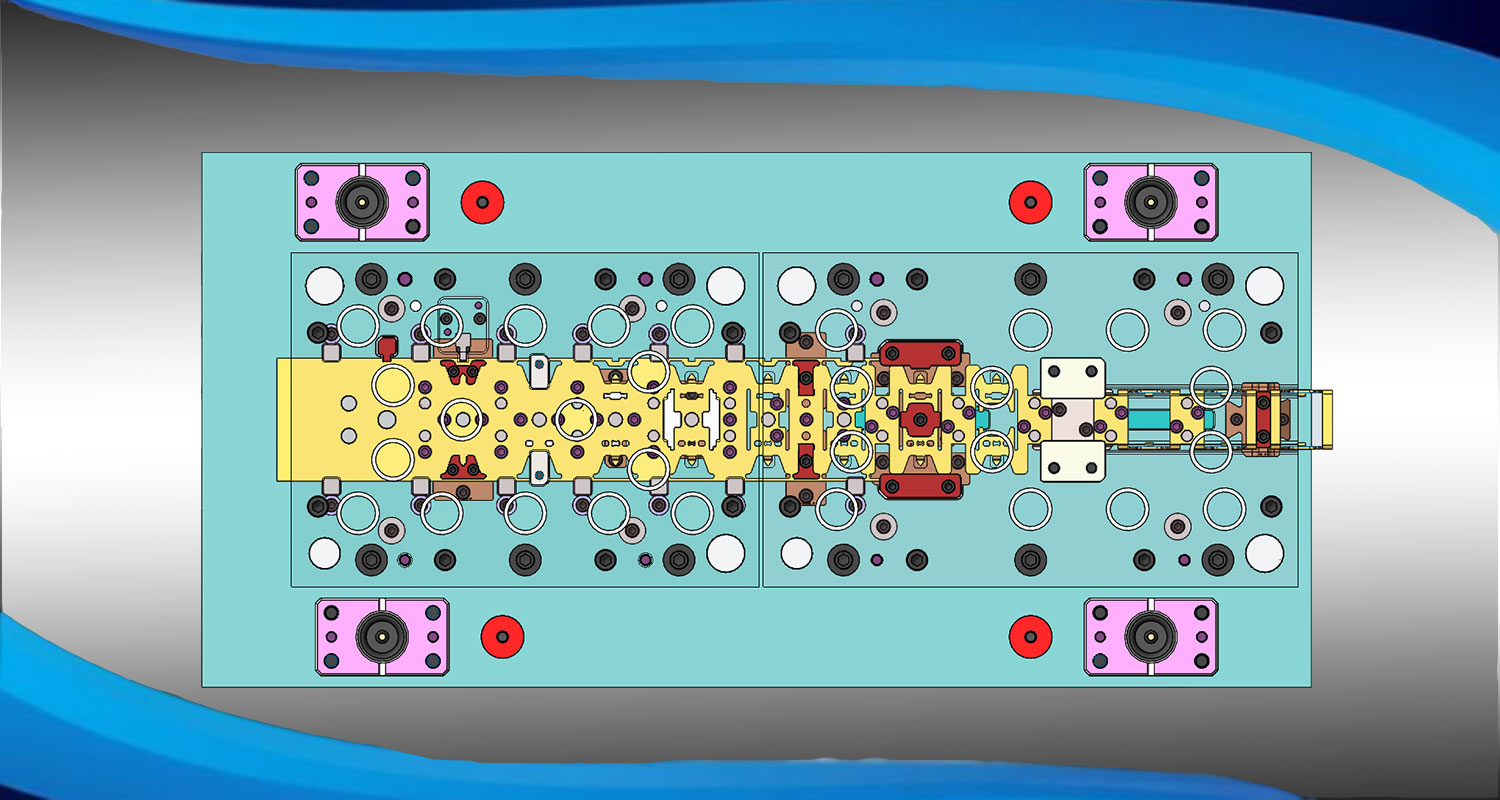

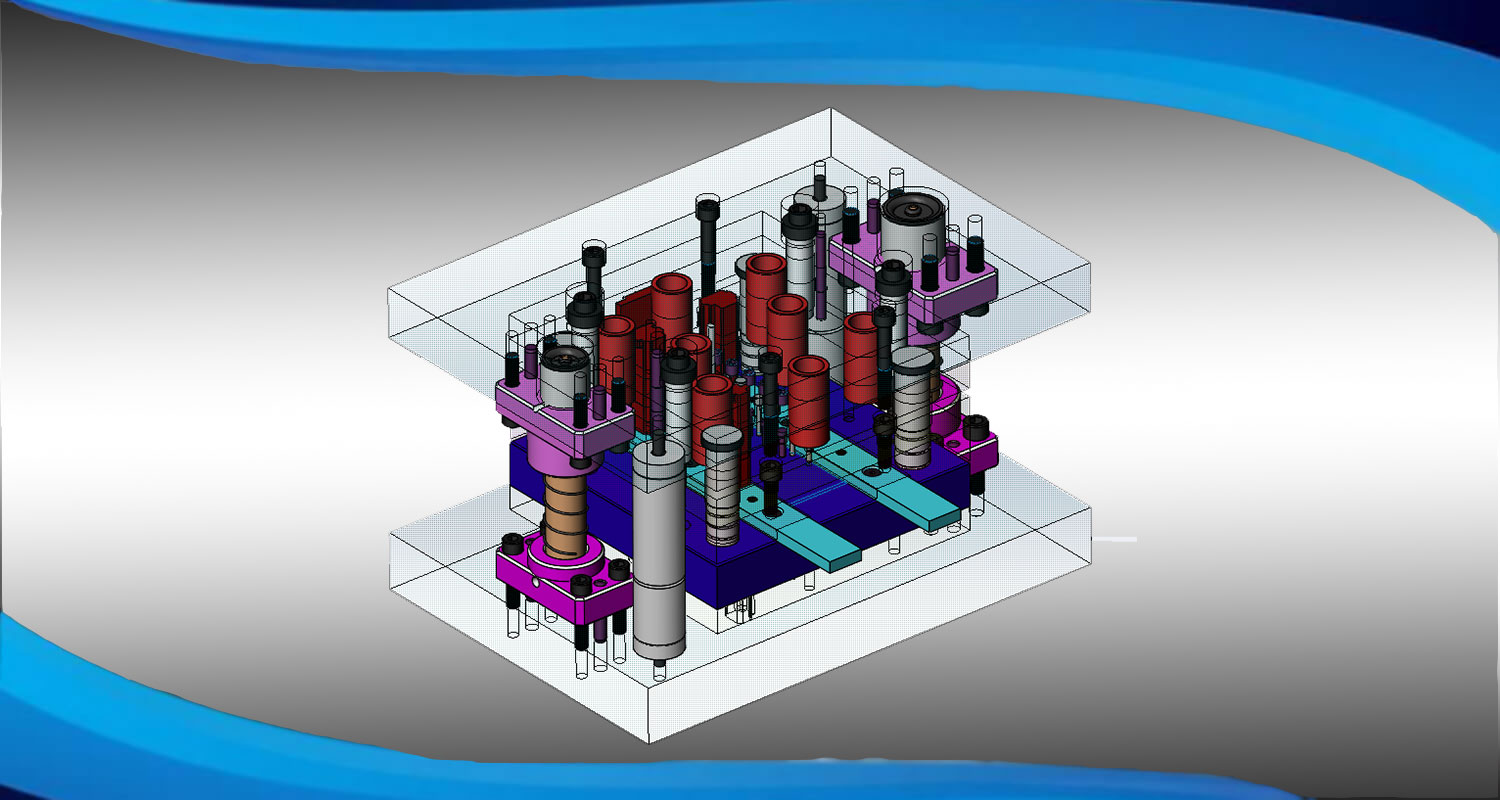

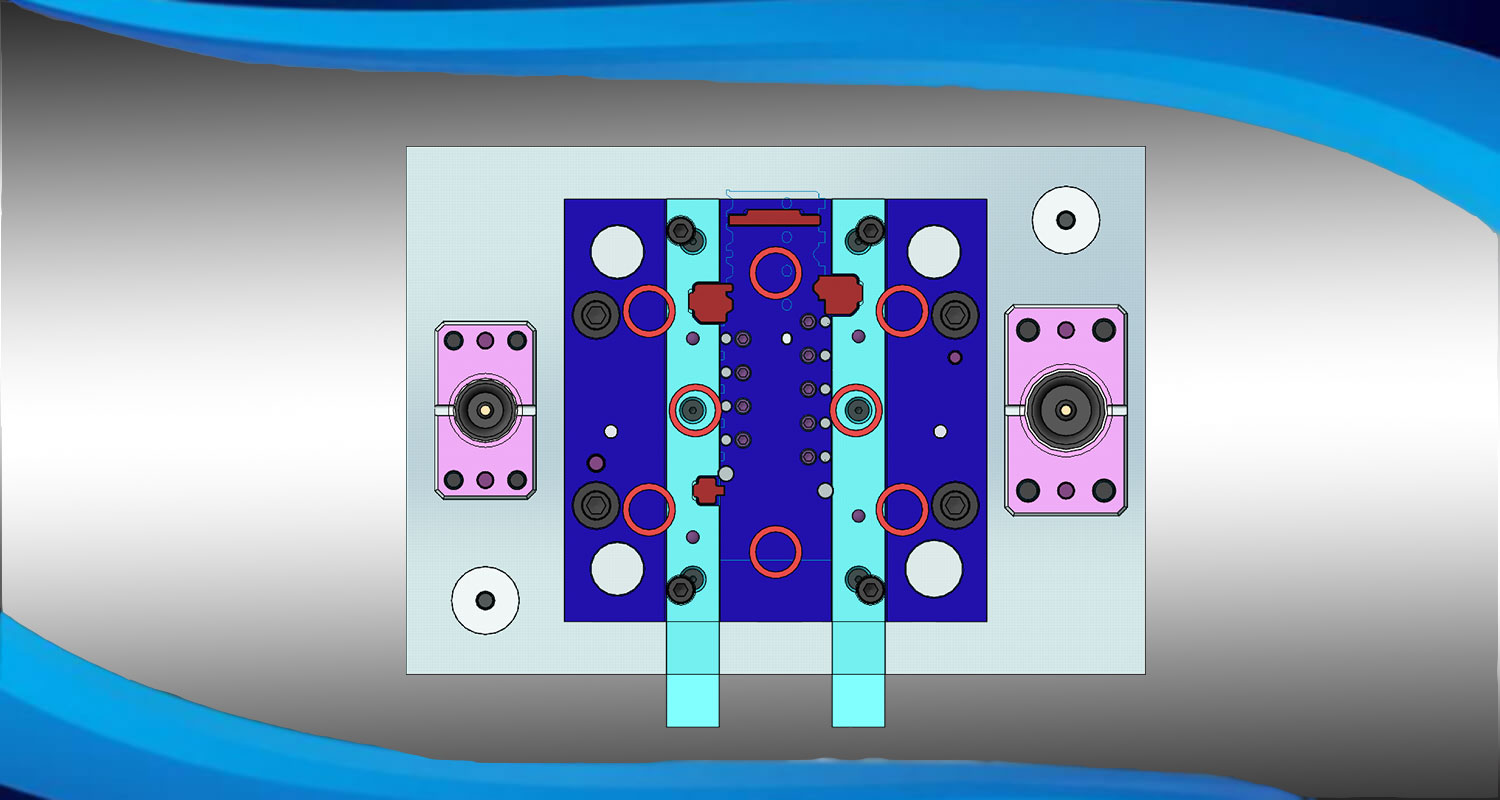

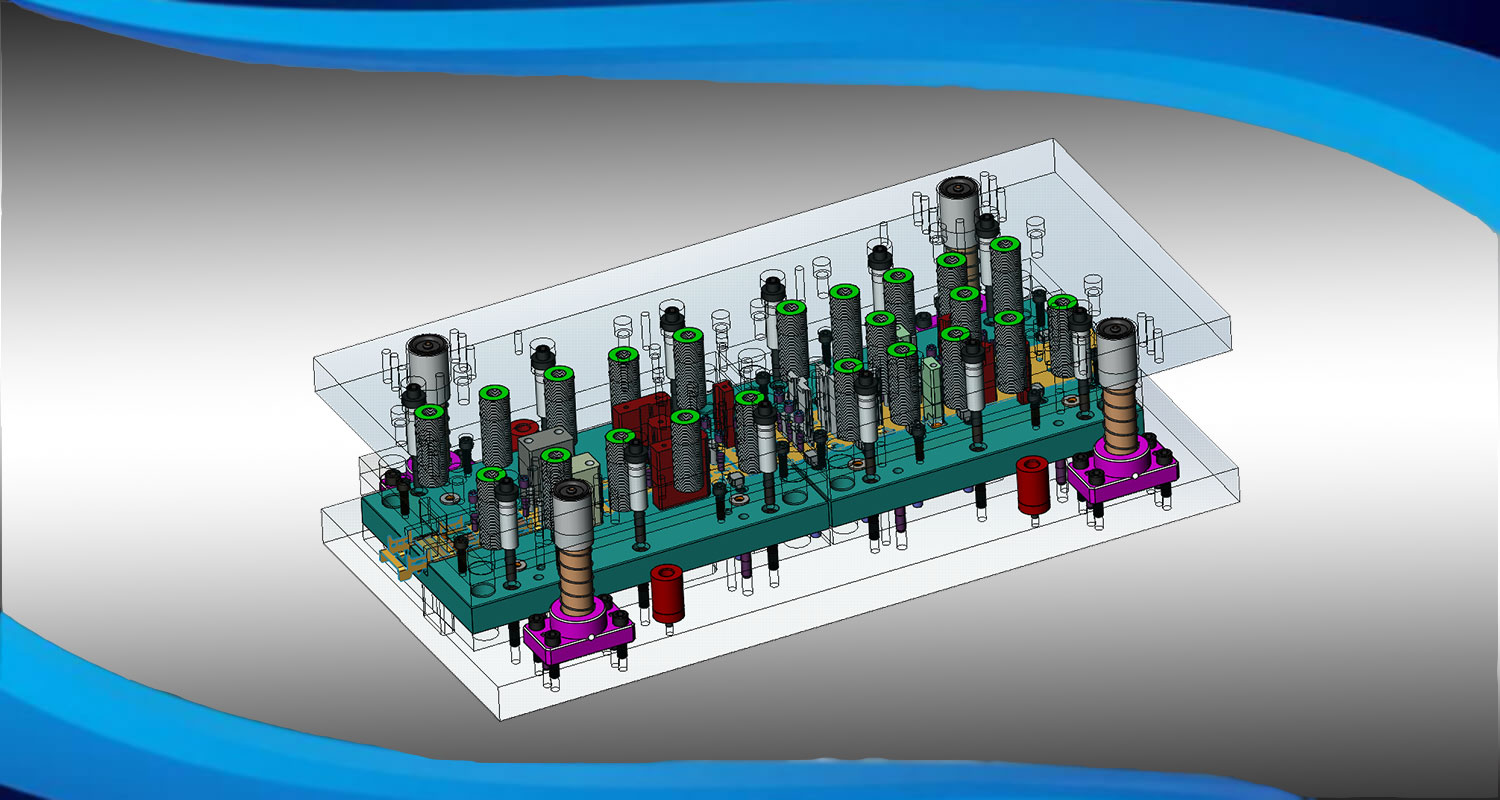

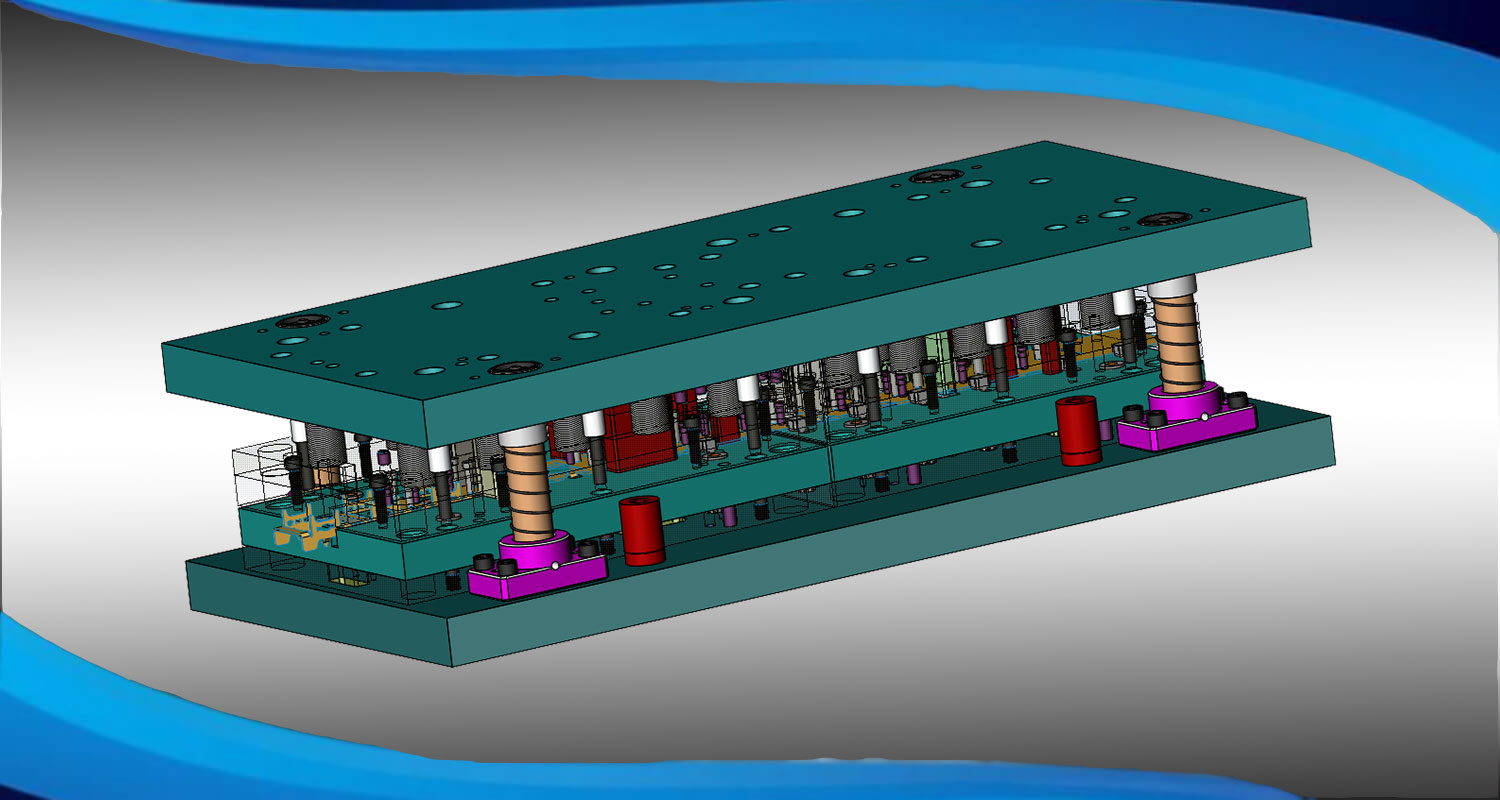

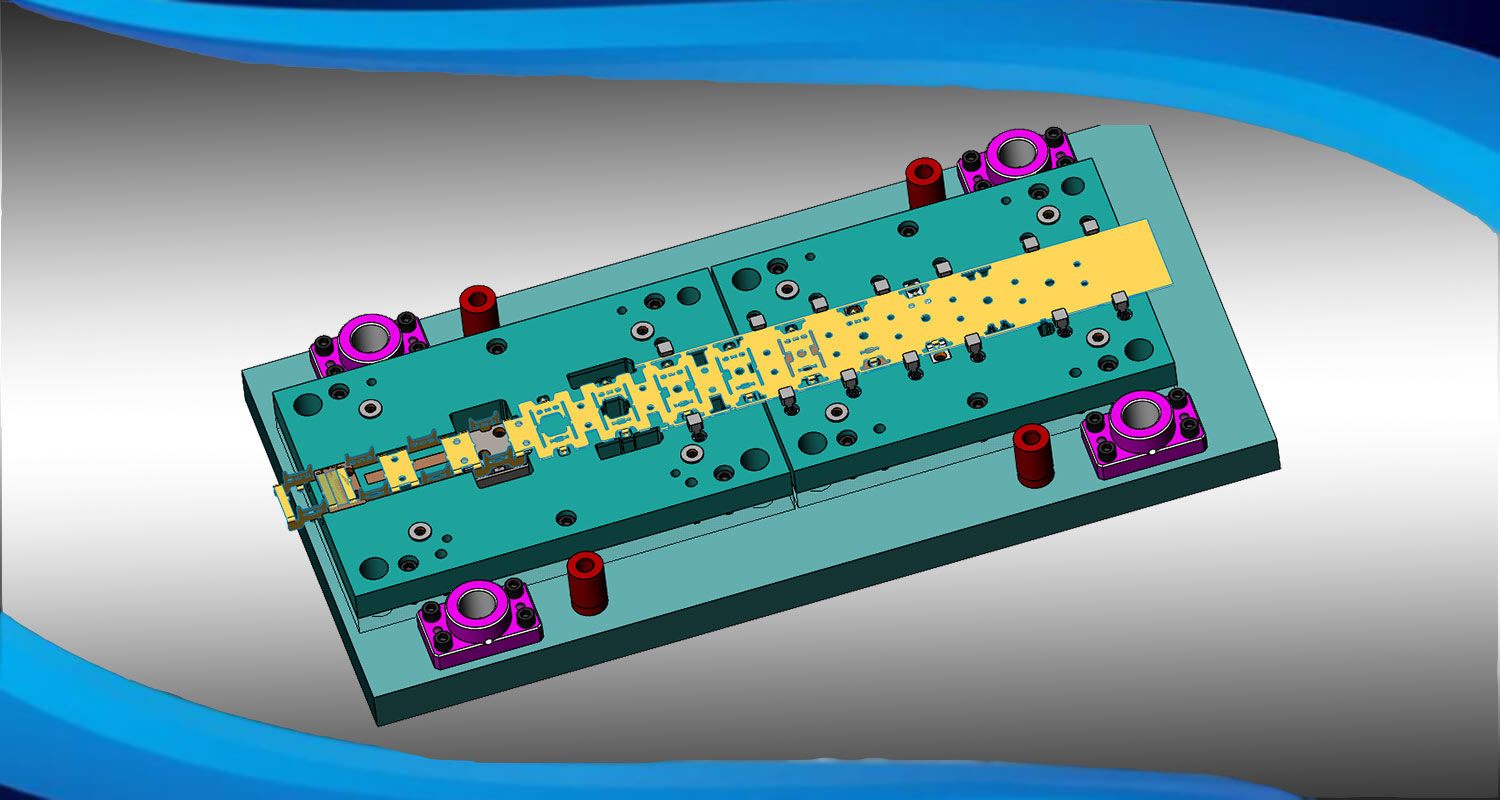

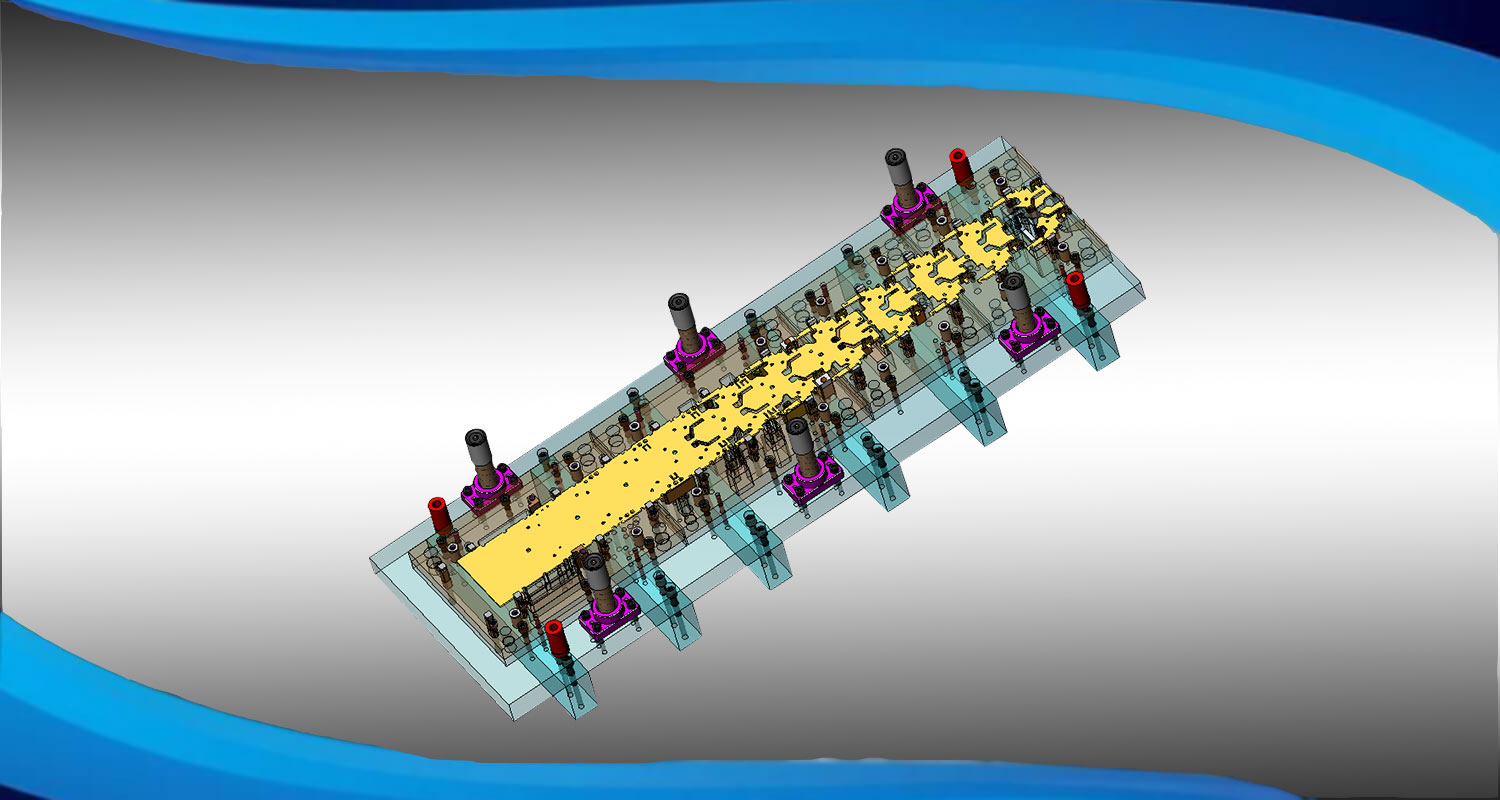

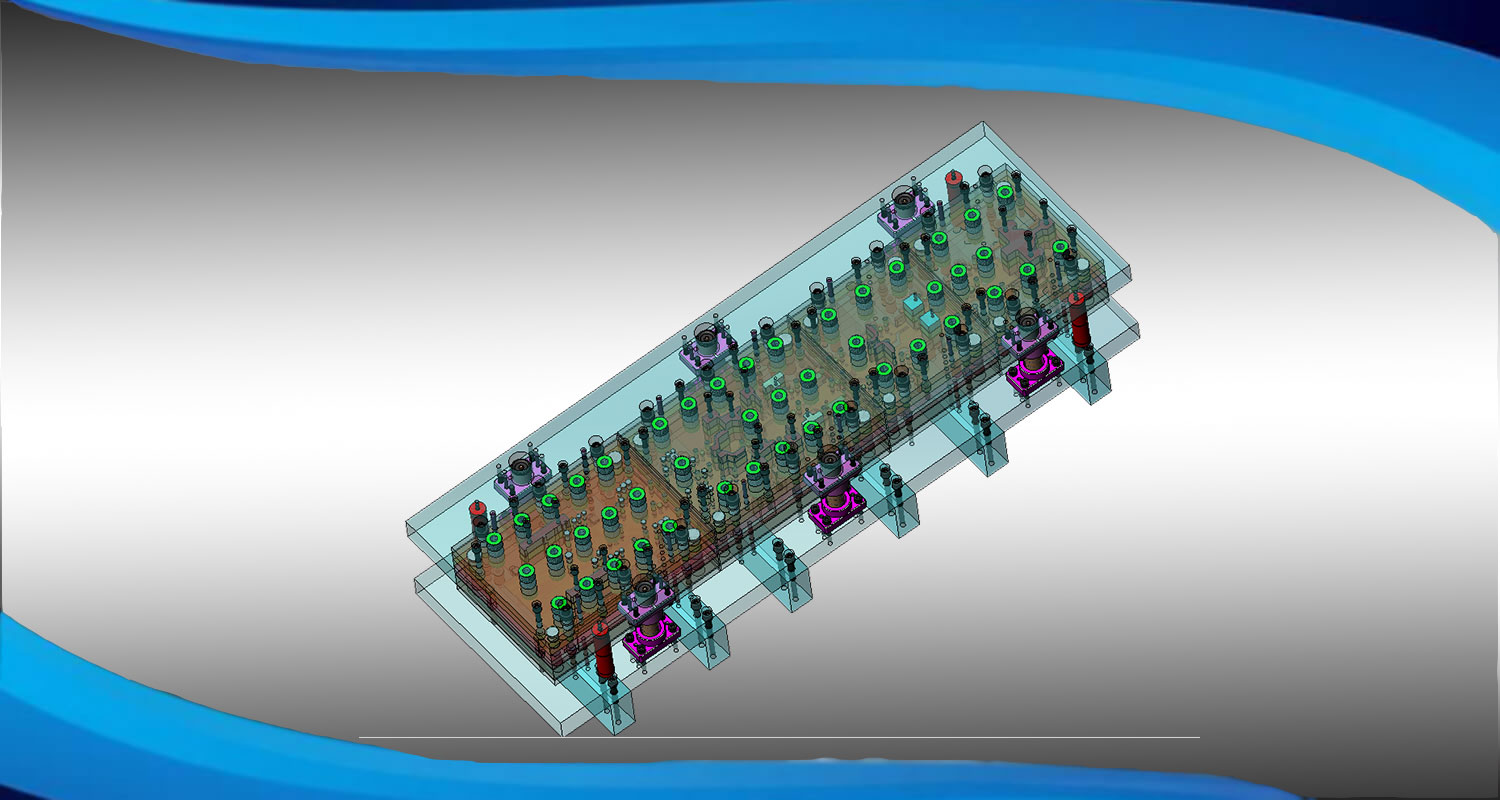

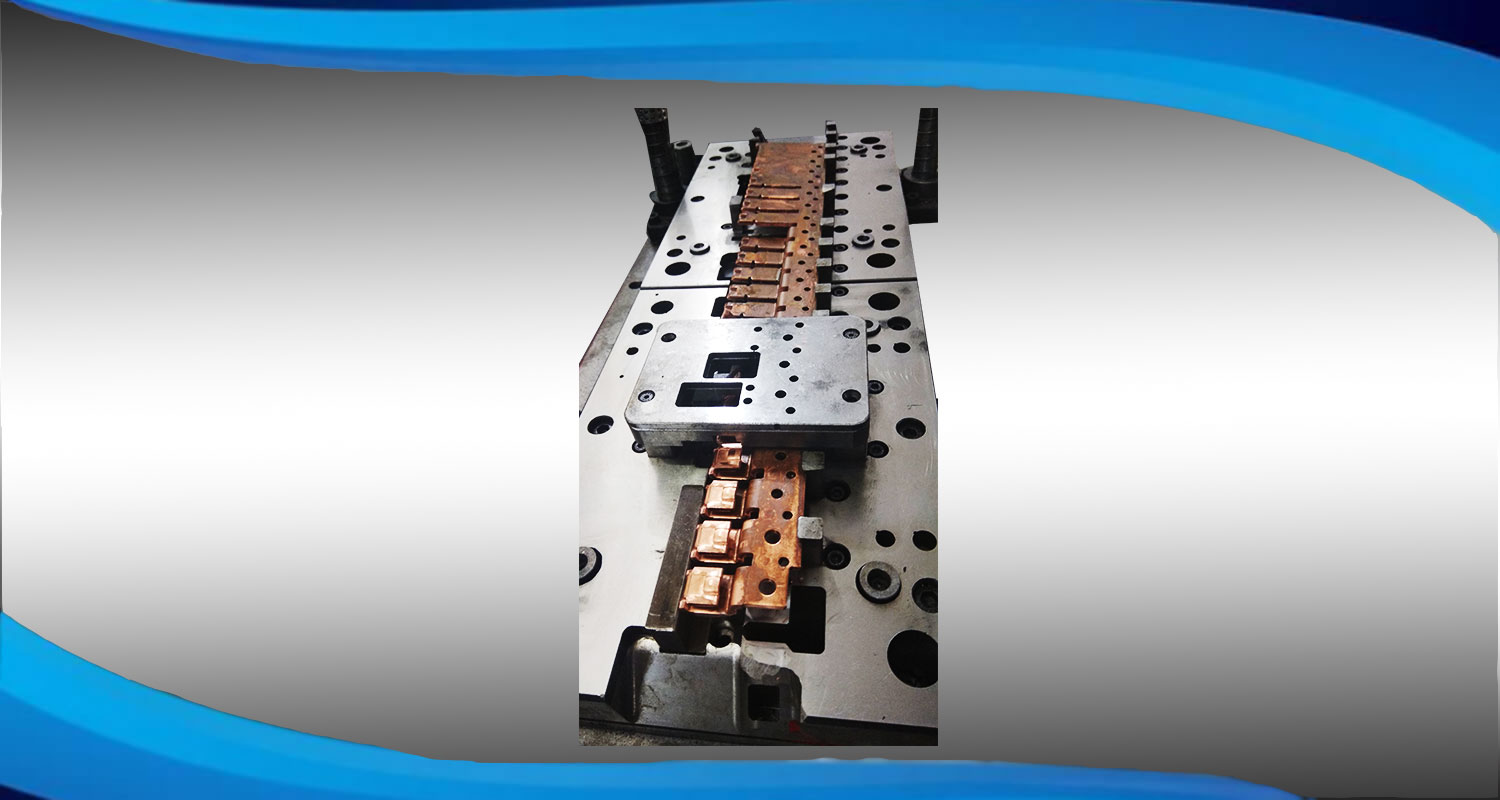

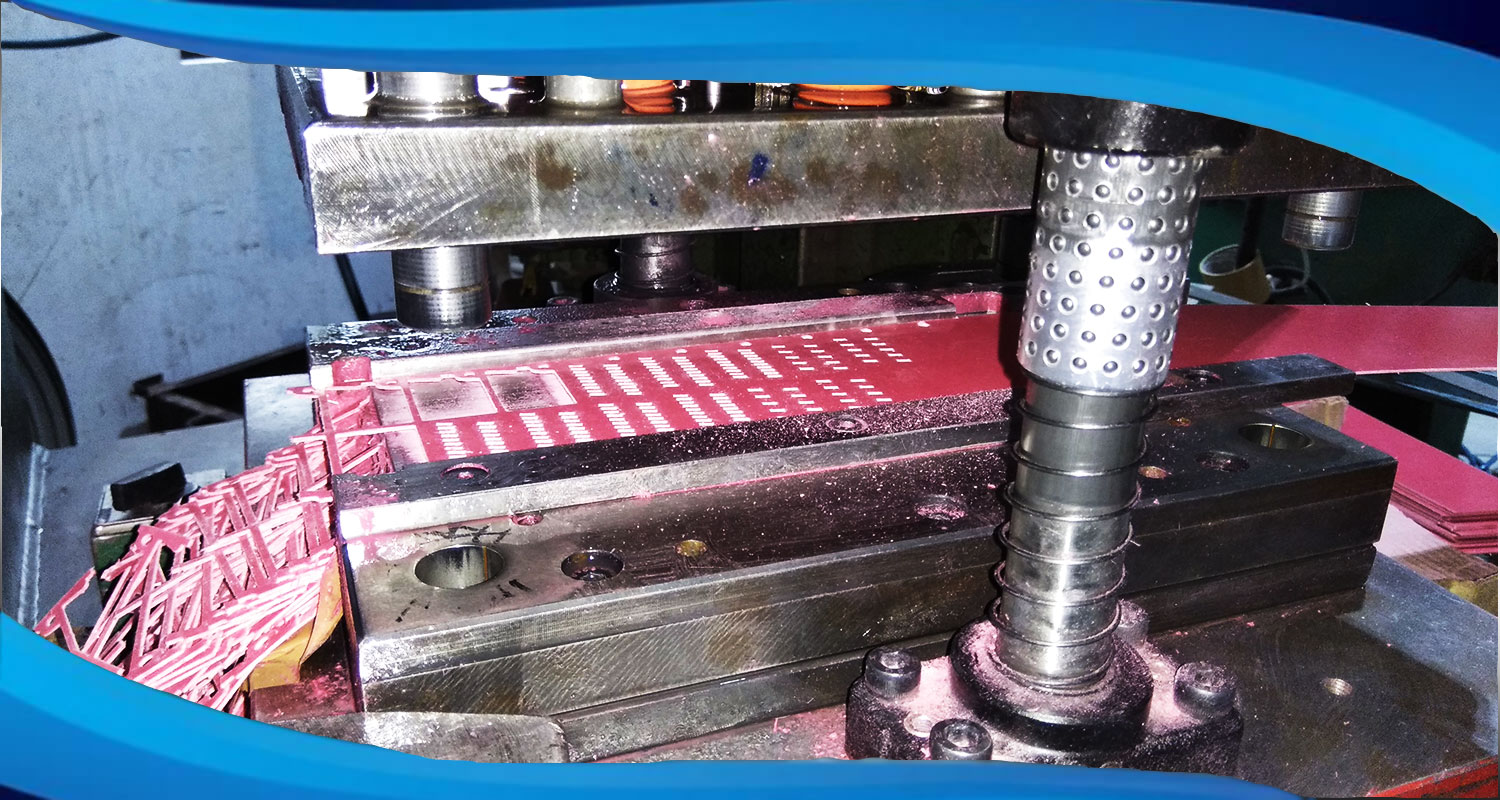

Progressive stamping is a metalworking method that can encompass punching, coining, bending and several other ways of modifying metal raw material, combined with an automatic feeding system. The feeding system pushes a strip of metal (as it unrolls from a coil) through all of the stations of a progressive stamping die.

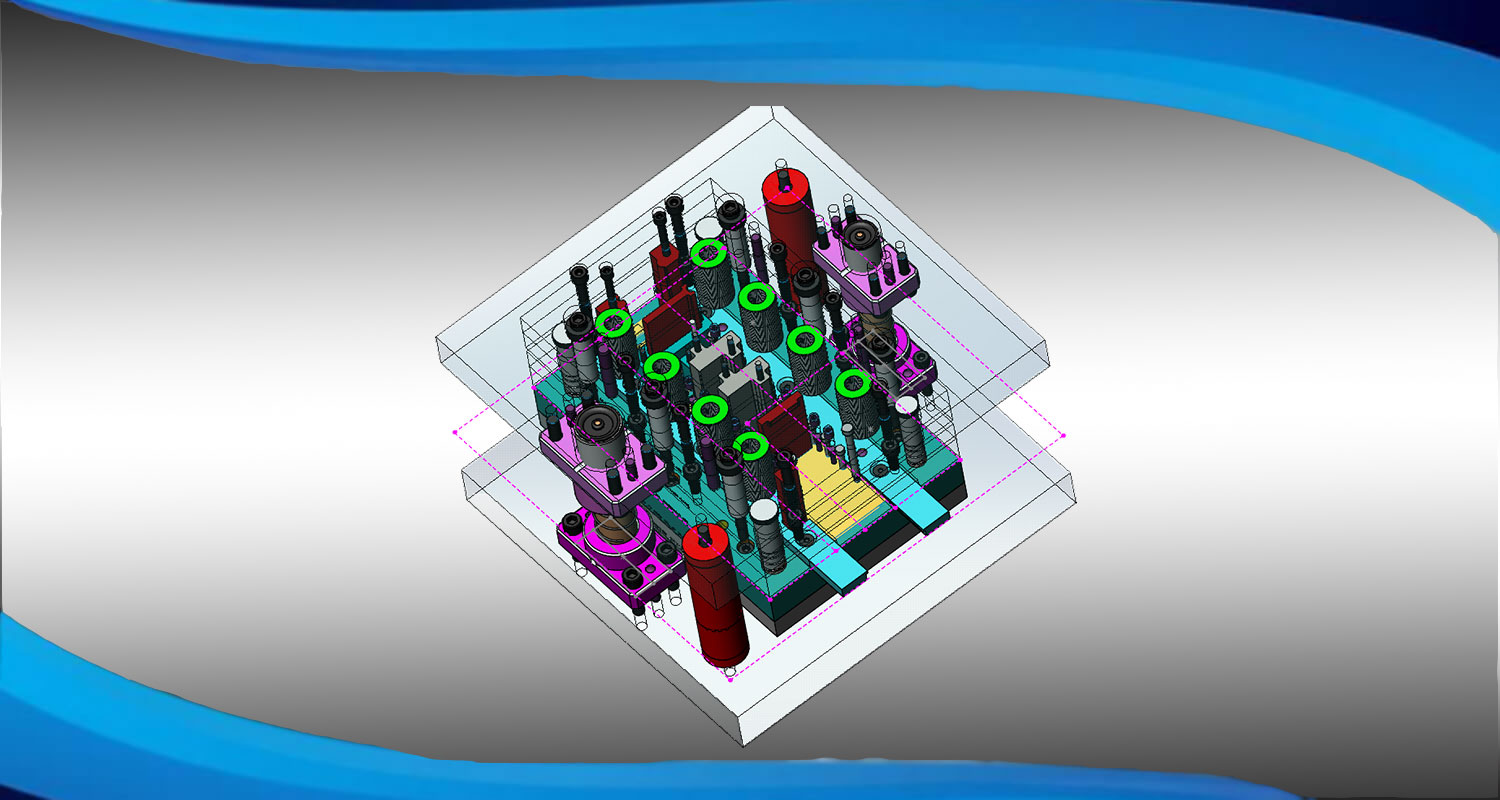

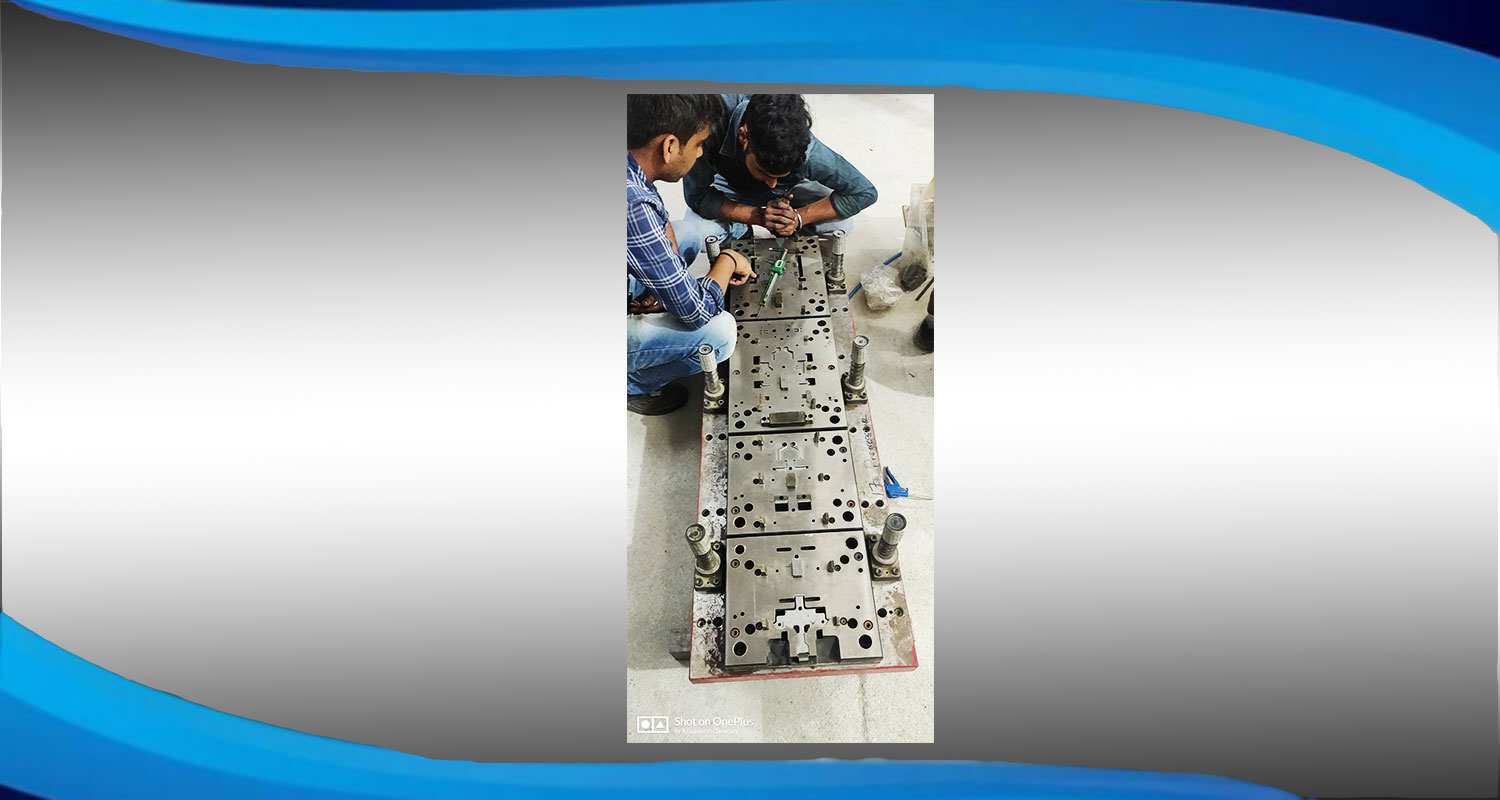

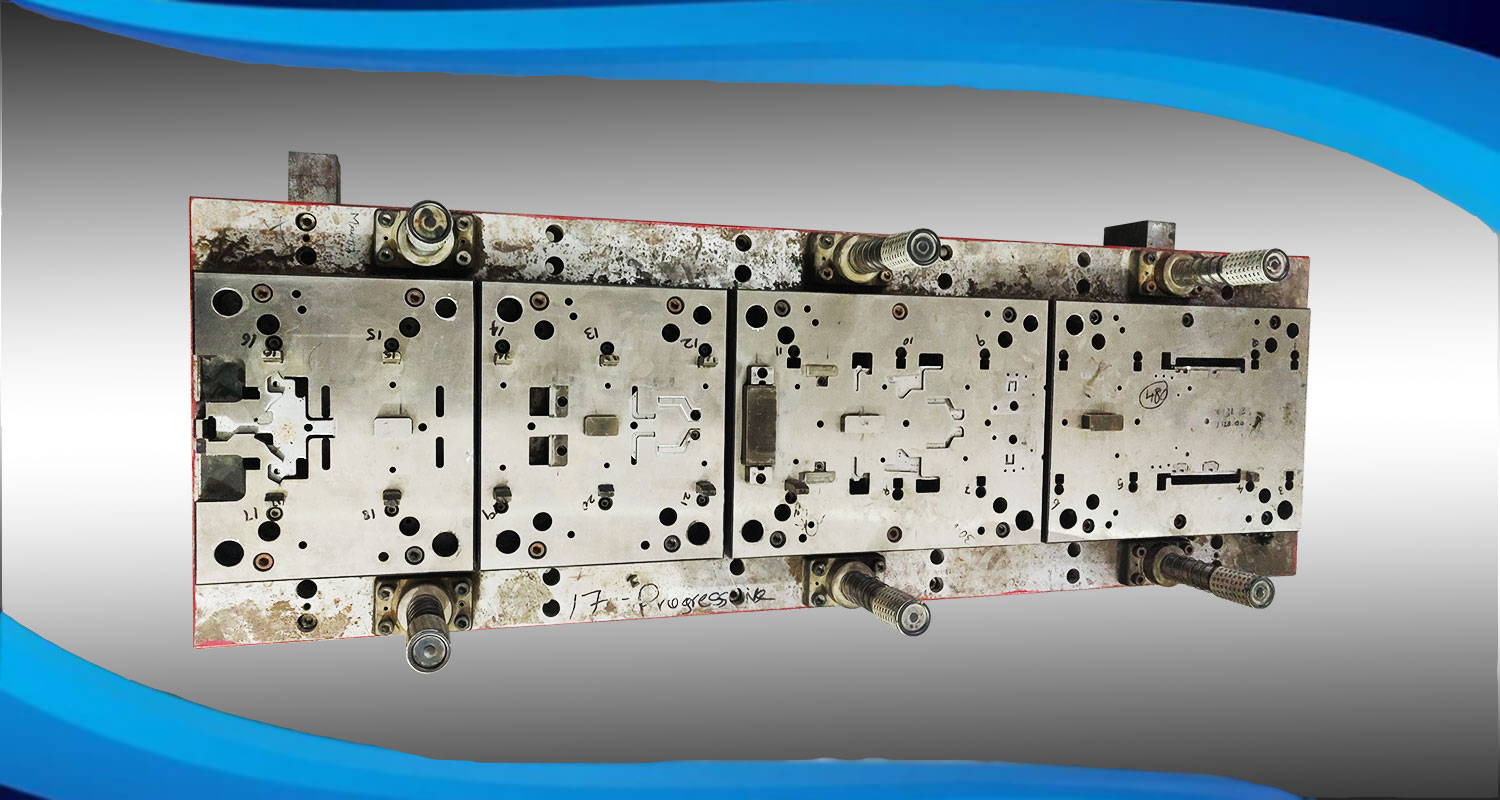

Progressive Tooling is the widely used by Techno Vision Tools to produce a wide range of parts and components. It is a metal stamping operation in which several procedures are performed in a progressive press. The process involves multiple stages in a fixed order to transform a metal strip into desired metal parts. The material is automatically fed from a spool into the press and continues from one stamping position to the next with each press stroke. Each station along the path carries out a certain operation simultaneously as the die descends until the part is complete in progressive tooling. Different steps are integrated within a single die, which allows for progressive tooling solutions in a quick, efficient and cost-effective manner.

Enquire Now